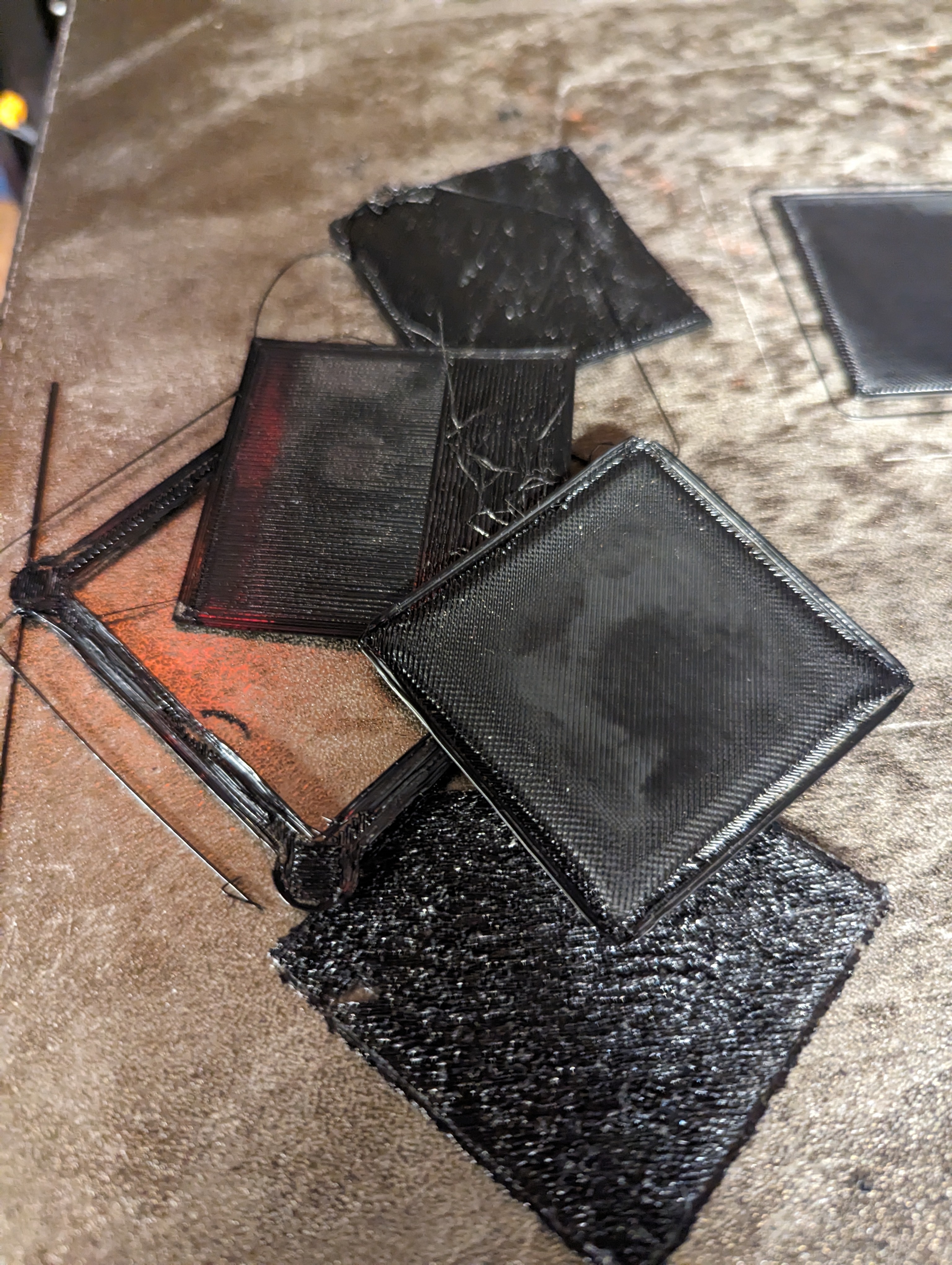

I’m trying to diagnose what tuning I need to get a smooth top layer on a solid print.

The picture you see is a 50mmx50mmx1mm square (cube([50x50x1]); in openscad) printed with a .4 nozzle. (5 layers)

For tuning on the problem, I have looked into:

- z_offset – tried all kinds of values and if I reduce it anymore, it doesn’t squish into the bed and the center part is exactly 1mm – so unlikely to be that.

- bed level – bltouch is working well

- extrusion (esteps or rotational_distance) - played with this a great deal and any less and i start to have under-extrusion in the center area.

- different filament – same with PLA, PETG and ABS

- Different slicer – same with PrusaSlicer or Cura

- Different speeds – one on the left was printed at 20mm/s – the right was printed at 150mm/s

I also cant find any guides out there that show this issue. Anybody with some suggestions or threads I can pull?

Pressure advance will solve some of your issues here. When reaching a corner, the head slows down but the filament is still pushed too fast and so it overflows. Pressure advance (in Klipper) can compensate for that.

I’ll check that out. I installed klipper yesterday for S&G – actually quite liking the flexibility it gives me. I see the guide.

Welcome to the deepest rabbit hole in 3D printing! Klipper is nice on the surface and absolutely mind blowing when you dig deeper. If you’re programming savvy, you can make it do basically anything. You can even install a script that runs shell scripts on the pi from the printer. You could make it control your coffee maker via home automation if you wanted. Lol. Anyways. Pressure advance is the key here.

Oh boy… Yes scripting comes easy to me. It’s why my default is openscad for making 3d models. :). I’m printing the pressure advance cube model now.

So… I still have some tuning.

I learned that you need to adjust retraction and z offset again after implementing pressure advance… But I’m close now.